ELECTROSTATIC

Definitions of electrostatic FIBCs

Concerning the aspects of the avoidance of electrostatic-ignition hazards, up to now four types of FIBCs (A, B, C and D) are in use according to their ability of charge dissipation and/or limiting the energy of possible discharges.

These four types of FIBCs are explained below:

FIBCs made from non-conductive materials without any measures against electrostatic charging.

As no electrical conductive material is interwoven in the fabric grounding and charge dissipation is hardly possible. Explosive atmospheres of gases as well as explosive atmospheres of dusts can be ignited. Therefore, a Type A FIBC must not be used to handle combustible dusts.

Safe way of usage: Used for the transportation of non flammable or non explosive goods. There should be no flammable or explosive solvent or gas in the environment.

Never Use: For the transportation of flammable or explosive goods. If there exists any flammable or explosive gas in the environment.

FIBCs made from non-conductive materials having a breakdown voltage not exceeding 6 kV.

This reliably prevents the ignition of explosive dust atmospheres while explosive gas atmospheres can still be ignited.

Like Type A, the Type B has no interwoven conductive materials. Thus, a Type B FIBC can be used where combustible dusts are present, but it shall not be used in hazardous areas.

Safe way of usage: Used for the transportation of dry and flammable products in powder shape. Manufactured either with or without liner. There should be no flammable or explosive solvent or gas in the environment.

Never Use: If there exists any flammable or explosive gas in the environment.

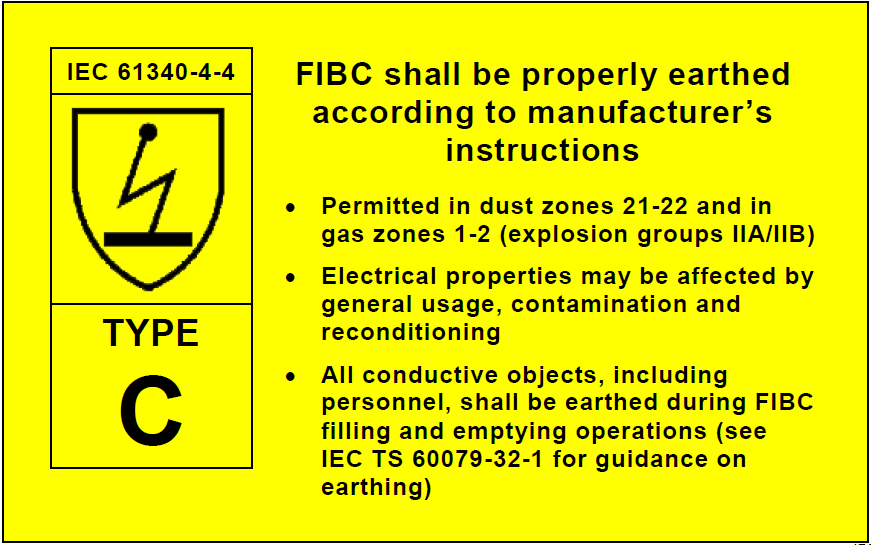

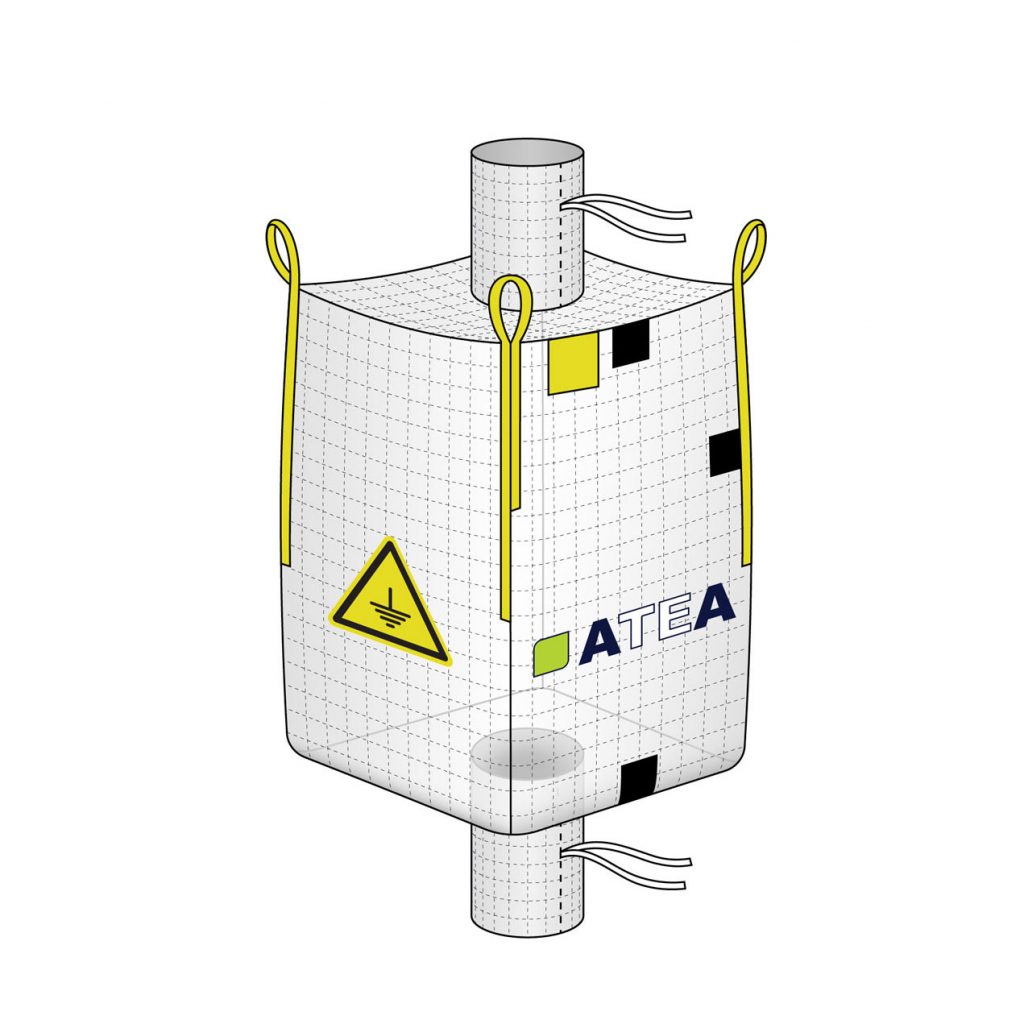

FIBCs normally made of non-conductive fabric with interwoven conductive threads forming a reliably interconnected grid of maximum 50 mm mesh size or having a distance between each other of less than 20 mm if the threads are in one direction only.

Those conductive threads must be interconnected with less than 107 ohm and must be grounded during filling and emptying operations.

Some Type C FIBCs have interconnected conductive loops to enable grounding via a (grounded) hoist system. When grounded properly there is no risk of incendive discharges. The inner or outer surfaces of the FIBC may have a thin coating. In this case the breakdown voltage to the conductive threads must not exceed 6 kV to avoid propagating brush discharges.

Thus, Type C FIBCs can be used in an environment with combustible dusts and/or explosive gases.

Safe way of usage: Used for flammable products in powder form. Should be used when there exists flammable and explosive solvents and gases in the environment.

Never Use: If the grounding mechanism is damaged or missing.

FIBCs made from non conductive materials containing an arrangement of conductive fibres which have no electrical contact to each other.

These FIBCs are not conductive but enable a certain charge dissipation into the environment via corona-effect. Grounding of a Type D FIBC is not possible.

Sometimes these bags are treated with an “antistatic coating” lowering the surface resistance of the fabric.

Because of the charge dissipation into the surrounding area via corona discharge, the Type D FIBC can easily charge insulated conductive objects or persons standing nearby.

Those objects or persons can, when contacting ground or grounded objects, cause electrostatic spark discharges capable of igniting explosive mixtures of gases or vapors.

Thus, Type D FIBCs may be used with combustible dusts

Safe way of usage: Used for flammable products in powder form. Should be used when there exists flammable and explosive solvents and gases in the environment.

Never Use: If the surface of the big bag is covered with any conductive material such as water or oil

Safe handling in potentially explosive environments

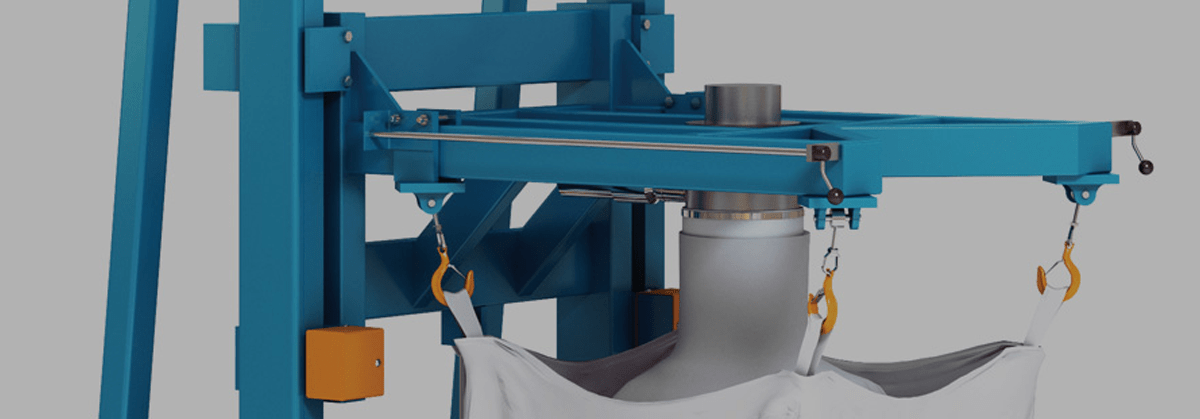

Some FIBC applications occur in potentially hazardous explosive atmospheres. Filling and Discharging creates static electricity. Fine powders with low (MIE) minimum ignition levels can create combustible dust clouds within the bag and surrounding environment.

Requirements | Type B | Type C | Type D |

|---|---|---|---|

Need for FIBC grounding & special handling equipment | |||

Compliance with EC 10/2011 & FDA food contact regulation | |||

Possibility to control the FIBC with metal detection | |||

Dissipation of static charge via Unique built in characteristics |

Are electrostatic charges dangerous?

Electrostatic charges are not dangerous by themselves but they may be dangerous when there is a risk of gas discharge.

Different types of gas discharges are as follows

- Brush discharges: In general they are capable of igniting gases and vapours but no dusts.

- Corona discharges: In general they are capable of igniting gases and vapours but no dusts.

- Spark discharges: In general they are capable of igniting gases and vapours but no dusts.

- Spark discharges: In general they are capable of igniting gases and vapours but no dusts.

- During the filling process the strongest electrostatic charge occurrence is to be expected. Transporting itself does not increase static electricity. During the emptying process, static charging must again be taken into

Generally, there are two situations that bear danger:

1-Explosive Materials – When explosive materials are filled into big bags the usage of conductive big bags is determined by the minimum ignition energy of the materials.

2-Explosive Environment – An explosive environment can be given by dust, gases or steam. The highest danger is given when the explosive environment consists of gases or steam.

MIE of dust | Non-flammable atmosphere | Dust zones 21-22 (1000 mJ MIE > 3 mJ) | Gas zones 1-2 (Groups IIA/IIB) or Dust zones 21-22 (MIE < 3 mJ) |

|---|---|---|---|

MIE > 1000 mJ | A, B, C, D | B, C, D | C, D |

1000 mJ > MIE > 3 mJ | B, C, D | B, C, D | C, D |

MIE < 1000 mJ | C, D | C, D | C, D |

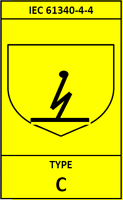

Type C FIBC labels

- Labels greater than 100 cm² in area shall not be made from material with surface resistivity greater than 1,0 × 10^12 Ω.

- Labels made from materials with surface resistivity less than 1,0 × 10^7 Ω can be used, provided the resistance to groundable point is less than 1,0 × 10^7 Ω.

- Labels made from materials with surface resistivity between 1,0 × 10^9 Ω and 1,0 × 10^12 Ω can be used.